1.UNO

New functions and design achieves four primary results

Quattro with excellent space and cost saving features offers greater value for money

Smallest Footprints in it’s category

Integrated mechanical, electrical,and 3-axis motion system

The oscillator.Power supply, & NC unit are combined into one compact system.The flying optic design allows for material to be proccesd in a very small space by moving only the cutting head while the material remains stationary. The compact structure contributes to ease of operation also.

2.DUE

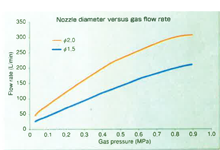

Reduced assist gas consumtion

A 1.5mm nozzle can be used on the Quattro reducing the flow rate of the assist gas.The translates into a sizable reduction in the assist gas cost

Extendes life of optics

Comprehensive measures have been implemented extendeing the services life of the cutting lens and the mirrors in the system

Extendes life of optics

Comprehensive measures have been implemented extendeing the services life of the cutting lens and the mirrors in the system

3.TRE

Ease of operation and flexible design

Open architecture

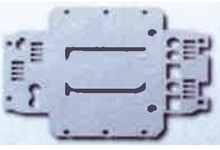

Loading or unload in three directions the cantilever design provides an open architecture making it easy top load and unload material from three different sides of the machine.Worksheets be loaded and prossed using manual repositioning

Skid table design

Flying optics and the need for securing the material with clamps.This makes it simple to process parts utilizing fixtures.or to cut irregular scrap or trimming

NC unit

A minimal amount of buttons needed for manula cutting.nozzle centerning. Multiple part mode. And other standard processing operators are arranged on the front panel.The NC unit can store 10 sets of cutting conditions for up to 90 different materials.it also stores cut conditions for each material

4.QUAT

Merits of simple construction

Simple design using a minimum of required features

By including only the necessary laser features on Quattro machine,the cost,Operating cost,and mainatanance on this simple design is greatly reduced.

Standardization of primary functions

Non-contact Z-axis sensor

The distance between the nozzle and the material is automatically detected by a sensor and held constant.this results in high accuracy processing with high speeds stability

Automatic assist gas selection

The assist gas in automatically selected in the cut condition screen in the NC control unit<

Clean Cut (non-Oxidation cutting)

The Clean cut process utilization nitrozen as an assist gas and can eliminate burning.Oxidation built up,and dross on stainless steel.

Clean Cut (non-Oxidation cutting)

The Clean cut process utilization nitrozen as an assist gas and can eliminate burning.Oxidation built up,and dross on stainless steel.

Greater ease of mainatanance

This simple.compact,integrated design has greatly reduced the amount of maintenance.It also makes it simpler to maintain due to the small footprints because every thing is so close together.

2 KW

Powerful compact machine for cutting small,medium,or even heavy guage parts

EZ Cut

The EZ cut system eliminates poor welds or poder coated paint peeling by elimiminating oxide build up on laser cut edges

Non-Contact Sensor for 3.75* focusing lens

Powerful for high quality of lighter guage material.

Dust collector

Can be stored below the oscillator further reducing footprints requirment

Contact Sensor

Ideal for cutting die boards.Plastics.and other no-matallic materials on which the capacitance head cannot be used.

Three-Way enclosure

Can enclose the operating parts of the machine in all three directions

Non-Contract Sensor for 7.5* focusing lens

Powerfully effective when cutting heavier guage material